Our Catalina 22 came with Arco 6 winches. Once a year your winches should be cleaned and maintained. Our haven't been serviced since we got the boat seven years ago and who knows how long before that, so it was well past time. While ours are Arco 6, the info below applies to virtually any single speed winches, for example Lewmar winches.

|

| Arco 6 Winch |

A sailboat winch is actually a relatively simple device. It is essentially a ratcheted drum that only turns clockwise. It provides mechanical advantage when pulling on lines. If more advantage is needed, a winch handle can be attached to the top which makes a bigger lever giving more mechanical advantage.

The winch works by having a cast outer drum that has serrations on the inner side, and an inner main shaft that the upper part turns. Set into the inner main shaft are a set of pawls. The pawls are pivoting metal blocks that are moved by springs. The springs push the pawls into the serrations in the drum. Because the pawls are mounted at an angle, as long at the winch is turned clockwise, the serrations will push the pawls out of the way. But if the winch tries to turn counter-clockwise, the pawls will be pushed by the springs into the serrations and stop the winch from moving.

To service the winch, I followed the directions on this web site: https://m17-375.com/2010/04/12/winch-maintenance-arco-6-style-winch/. Another web site worth looking at is the Stingy Sailor's. Also Emily & Clark's Adventure has a nice video on winch maintenance for a two-speed winch. The basic idea is you open the winch, clean out any gunk that has accumulated, replace any spring that are no longer working, grease it all back up, and put it back together. If you are working over water, it is highly recommended to make a box that goes around the winch to keep any parts from jumping into the water.

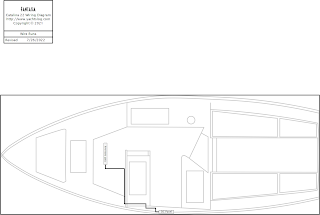

|

| Winch Box |

I started by removing the spring ring at the top that holds the winch together with two small flat blade screwdrivers. I noticed that there were springs that were sticking out, obviously not right. After removing these springs with needle nose pliers, I proceeded to remove the pawls. There are two levels to the winch: lower pawls that are attached to the part of the shaft that doesn't spin, and upper pawls that are attached to the part that does spin. On the Arco 6, there are a total of four pawls, but on a bigger winch there may be more. There are two half disks that fit between the upper pawls and the lower pawls. With the outer shell removed, these simply slide out.

The winch is designed to be serviced.There is a small indent in the upper part of the winch. By spinning the indent above the lower pawls, they can be slid up and removed. This then makes the upper pawls removable. By sliding them into the space where the lower pawls were, they can then be removed the same way. To remove the pawls, they must be pushed in, or the angle won't be right. After removing the pawls, all the parts should be cleaned in a solvent like turpentine or mineral spirits. Then the whole thing should be put back together.

|

| Items needed to service winch, plus lots and lots of paper towels. |

And that is where we ran into the first hitch. The springs on the Arco 6 were mangled and wouldn't stay on the pawls. These springs and pawls were not designed well, with little loops of spring that go over the ends of the pawls to hold them in place but pop out easily. I couldn't find replacement springs of the same design. However, the pawls of the Arco 6 can be replaced with Lewmar small winch pawls. The Lewmar pawls are a little shorter, but work just fine. The springs mount in the middle rather than the ends. Unfortunately, the kit comes with six pawls, so it will take two kits to service both winches, leaving four extra pawls. After replacing the pawls with the new pawls, the springs can be serviced in the future for almost nothing (I found one place that sells them for 15 cents each), and extra springs come with the Lewmar pawls.

|

| Pawl from the Arco 6 |

I greased the movable parts and parts that come into contact with each other with Harken winch grease. The tube says to not grease the pawls. After reversing the disassembly procedure with the new pawls, the winch went back together nicely and give very nice satisfying clicks when rotating.

|

| Cleaned winch with Lewmar pawls |